By Kelly-Ann Mattis

Did you know 3D-printed lithophanes can also be made with 3D Resin & PETG?

Yes!

Some people even get better results by printing lithophanes in 3D Resin or PETG.

It’s situational on what is best. It can depend on the theme of the image, the use on where you want to place the lithophane & of course your own preferences.

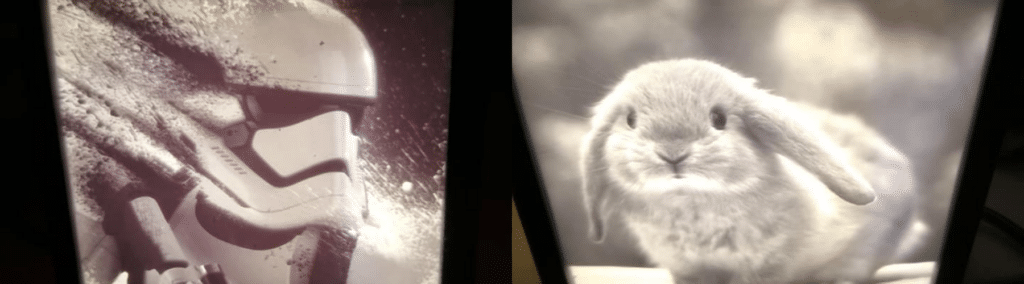

Every material provides a slightly different look to the lithophane.

It also requires a different approach to making lithophanes with different materials. In this post, Kelly-Ann Mattis, shares her journey on working with these different materials!

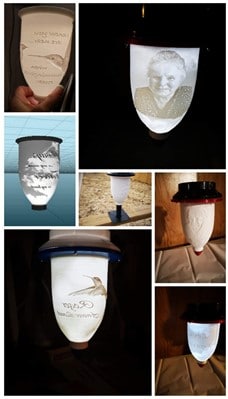

I have been experimenting with colorings as white resin & yellows quite a bit. At first, I started by adding a blue die to the white. Once cured it turned things kind of green which, to me, wasn’t appealing. I like the lithophanes to look nice even if not lit up and since most of mine hang in a window, the green didn’t look nice.

I liked the way the darks and contrasts come out in the grey resins that I had seen done. But just grey needs far more light than a window can produce so it was too dark. I started mixing. I tried 3-1; 4-1; 5-1… and settled on 7/8-1. This provided just enough color to mitigate the yellowness of the cure making it more of aged porcelain while unlit while bringing in the benefit of the darker tones and contrasts. They now look pretty sitting in the window all the time.

Printing lithophanes with resin. I can go as thin as .6 and 3.8/4 as max. I prefer 3.8 as my borders are usually 4 and it gives a bit of definition. With PETG/PLA my min was best at .8 and max 3.6/3.8.

I have been experimenting with printing flat as opposed to standing as well.

Laying flat gives you a print time of approx. 25minutes where standing is about 6hrs. Now on my Phrozen mighty, I can run 18-20 lithophanes on the plate. Without supports. The flat ones are still really nice, but the standing ones just have a nice definition to them. The biggest point though if you’re

are going to do lithophanes in resin. Invest in a flex plate. They are really difficult to get off the build plate without!

I have been working with a lot of people online trying to use PETG for lithophanes. Here is what I have been coaching based on my experiences…

PETG cannot be compared to PLA. It is a completely different animal and needs to be treated as such.

I hope this helps. As you can see PETG is very different from PLA (Almost opposite..lol) But is beautiful and shouldn’t be ignored especially for window things and outside.

PETG lithophanes Made by Kelly-Ann

I hope this helps. As you can seen PETG is very different to PLA (Almost opposite..lol) But is beautiful and shouldn’t be ignored especially for window things and outside.

Free online designing software that helps you create high-quality 3D printed lithophanes. It’s a simple yet powerful cross-platform lithophane maker.